By Pat Ryan – Arvo

Your suppliers are your external manufacturing department. They do what you don’t want to do; because it’s technologically impractical, they are better than you, you are concentrating on other things, or it could tie-up your resources.

FACT: You are trusting them with your future

Developing good connections with suppliers—sometimes called Supplier Relationship Management—is critical to business success.

Businesses are increasingly relying on suppliers to help reduce costs, innovate, improve quality and reduce lead time. Good relationships with suppliers can provide a competitive advantage.

First-rate supplier relations require continuous, long-term effort. Not all suppliers should be treated as special suppliers. Some of the suppliers may not be suitable for developing relationships.

- Evaluate all suppliers—Make sure they are the best ones for your business and that their products meet your needs. You want suppliers who are aligned with your strategy.

- Integrate key suppliers into your business—Learn how they operate, and make sure your systems work seamlessly with theirs in areas such as invoicing and order fulfilment.

- Collaborate on quality improvement, problem-solving and product development—Work together to improve capabilities and adopt best practices on both sides.

- Measure performance continually—Have structured ongoing discussions with your key suppliers about how to improve.

Ultimately, the idea is to work together as partners so both sides prosper.

BE BRAVE – NOT ALL COMPANIES CAN DEVELOP AND MAINTAIN A SUPPLIER RELATIONSHIP PROGRAMME.

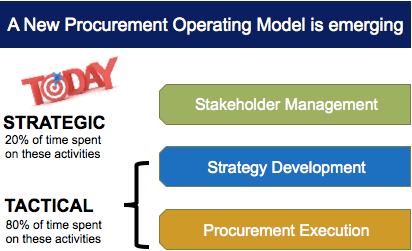

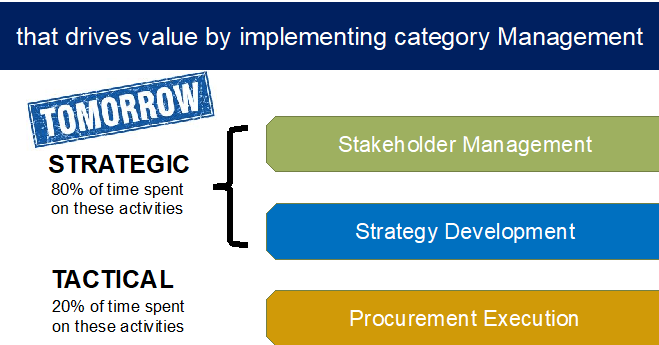

Sometimes companies focus just on the short term and only demand cost reductions from suppliers, rather than thinking strategically. That doesn’t help in the long run.

Do’s and don’ts of supplier relationships

- DO—Take a long-term approach to supplier relationships. Commit to shared prosperity and mutual development. Help suppliers boost their technical and problem-solving capabilities.

- DO—Understand in detail how your key suppliers work. See how they operate, and learn their culture to ensure mutual trust and strong partnerships.

- DO—Periodically evaluate the performance of key suppliers with scorecards, and periodically scan the market for better and/or more cost-effective alternatives. While you want to nurture strong relationships with suppliers, you don’t want to become captive to them.

- DON’T—Focus only on short-term goals, such as cost-cutting. Don’t insist on unreasonable payment terms or pressure suppliers to assume the cost and risk of holding the bulk of your inventory.

- DON’T—Focus your efforts on all your suppliers. Save your special collaboration for only a handful of key strategic partners. Anything more is unsustainable.